The Role of PCB Manufacturers in Advancing Modern Circuit Designs

In today’s fast-paced world of electronics, circuit boards are the heart of nearly every device we use. From smartphones to computers and medical devices, the printed circuit board (PCB) plays a vital role in making these gadgets work. PCB Manufacturers are key players in designing and creating these complex boards. Their work directly influences the performance, reliability, and functionality of modern technology.

What is a PCB?

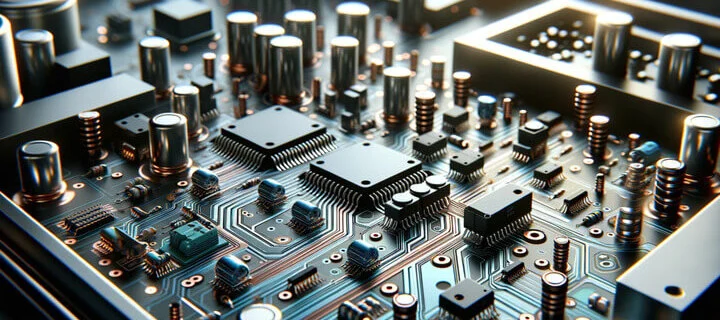

A PCB (Printed Circuit Board) is a thin board made from insulating materials, with conductive pathways that connect electronic components. These components include chips, resistors, capacitors, and other parts necessary for a device to function. The PCB provides mechanical support and electrical connections between these components.

PCBs are essential in almost all modern electronics, including consumer devices, industrial equipment, and medical technology.

The Evolution of PCB Design

The design of PCBs has changed a lot over the years. Initially, PCBs were simple boards with a few components. However, as electronics became more advanced, the need for more complex and efficient PCBs grew. Today, designs are much smaller, faster, and more intricate.

PCB manufacturers have responded to these challenges by developing advanced techniques, such as multi-layer boards, flexible circuits, and high-density interconnects (HDI). These innovations have allowed for smaller, more powerful devices. Modern PCBs can handle complex tasks and support high-speed data transmission.

PCB Manufacturers and Innovation

PCB manufacturers are crucial in driving innovation in electronics. As technology advances, so do the requirements for PCBs. These manufacturers invest in research and development to create cutting-edge designs that meet the needs of the tech industry.

They collaborate with engineers to build customized PCBs for specific applications, such as wearable devices, automotive systems, or medical equipment. By using advanced materials, like high-frequency laminates and heat-resistant substrates, PCB manufacturers ensure that devices perform efficiently and reliably.

The Importance of Quality in PCB Manufacturing

Quality control is a top priority for PCB manufacturers. A minor flaw in the design or manufacturing process can cause a device to malfunction or even fail. This is especially critical in sectors like healthcare, where precision and reliability are essential.

PCB manufacturers use various testing methods to ensure the boards meet high standards. These tests include visual inspections, electrical testing, and stress testing. By maintaining strict quality control, manufacturers can guarantee that the PCBs will perform well in real-world conditions.

Meeting the Demands of Modern Electronics

Today’s electronics are becoming more powerful and smaller, which presents new challenges for PCB manufacturers. Devices need faster processing speeds, more memory, and better power management, all in smaller, more compact designs.

To meet these demands, PCB manufacturers use advanced techniques such as:

- Miniaturization: Making smaller, more compact PCBs without compromising performance.

- HDI (High-Density Interconnects): Using smaller components and tighter spacing to create more powerful circuits.

- Flexible PCBs: Allowing the boards to bend and fit into tight spaces, which is ideal for wearable devices or foldable phones.

These advancements help ensure that modern devices can continue to evolve and meet the needs of consumers.

PCB Manufacturers in the Automotive Industry

The automotive industry is one area where PCB manufacturers play a significant role. Modern cars rely heavily on electronics for everything from navigation systems to safety features. PCBs are used in a variety of automotive applications, including engine control units, infotainment systems, and advanced driver-assistance systems (ADAS).

As cars become more automated, the demand for reliable, high-performance PCBs increases. Manufacturers are constantly working on creating boards that can handle extreme temperatures, vibrations, and long-term use. They are also developing PCBs that support new technologies like electric vehicles (EVs) and autonomous driving.

The Role of PCB Manufacturers in Sustainability

Sustainability is a growing concern in the electronics industry. PCB manufacturers are looking for ways to reduce the environmental impact of their products. This includes using eco-friendly materials, reducing waste in the manufacturing process, and developing recyclable PCBs.

Some manufacturers are focusing on creating lead-free PCBs and using biodegradable materials. This shift toward sustainability is essential as the world continues to move toward greener practices in technology manufacturing.

Future Trends in PCB Manufacturing

As technology continues to advance, so will the role of PCB manufacturers. Several trends are expected to shape the future of PCB design and manufacturing:

- 5G Technology: With the rise of 5G, PCBs will need to support faster data transmission speeds and greater bandwidth. Manufacturers are developing specialized PCBs for 5G applications.

- IoT (Internet of Things): As more devices become connected, there will be a greater demand for compact and efficient PCBs to power IoT devices.

- AI and Machine Learning: PCBs for artificial intelligence applications will require faster processing speeds and greater power efficiency, pushing manufacturers to create more advanced designs.

- Smart Devices: The demand for smart home devices and wearables will continue to grow, requiring more flexible, reliable, and miniaturized PCBs.

Conclusion

PCB manufacturers are essential in advancing modern circuit designs. They are responsible for the creation of highly complex and reliable circuit boards that power our electronics. Through innovation, quality control, and sustainability efforts, they continue to meet the evolving demands of the tech industry. As electronics become more advanced, the role of PCB manufacturers will only grow, supporting the development of new devices and technologies that improve our daily lives.